AI for CHWS/CHWR/CHWP: Chilled Water Piping Takeoffs from PDFs

Why Estimators Use AI Assistance

Save precious time

Reduce hours spent searching through MEP drawings and schedules so you can concentrate on pricing and strategy.

Keep numbers traceable

Draft outputs point back to source sheets, making reviews and clarifications easier with your team and clients.

Stay flexible

Addenda and changes happen. It’s simpler to update and re-issue a takeoff when groundwork is already prepared for you.

Upload your MEP PDFs and run a simple prompt. A draft chilled water piping takeoff is prepared and you’re notified when processing is completed.

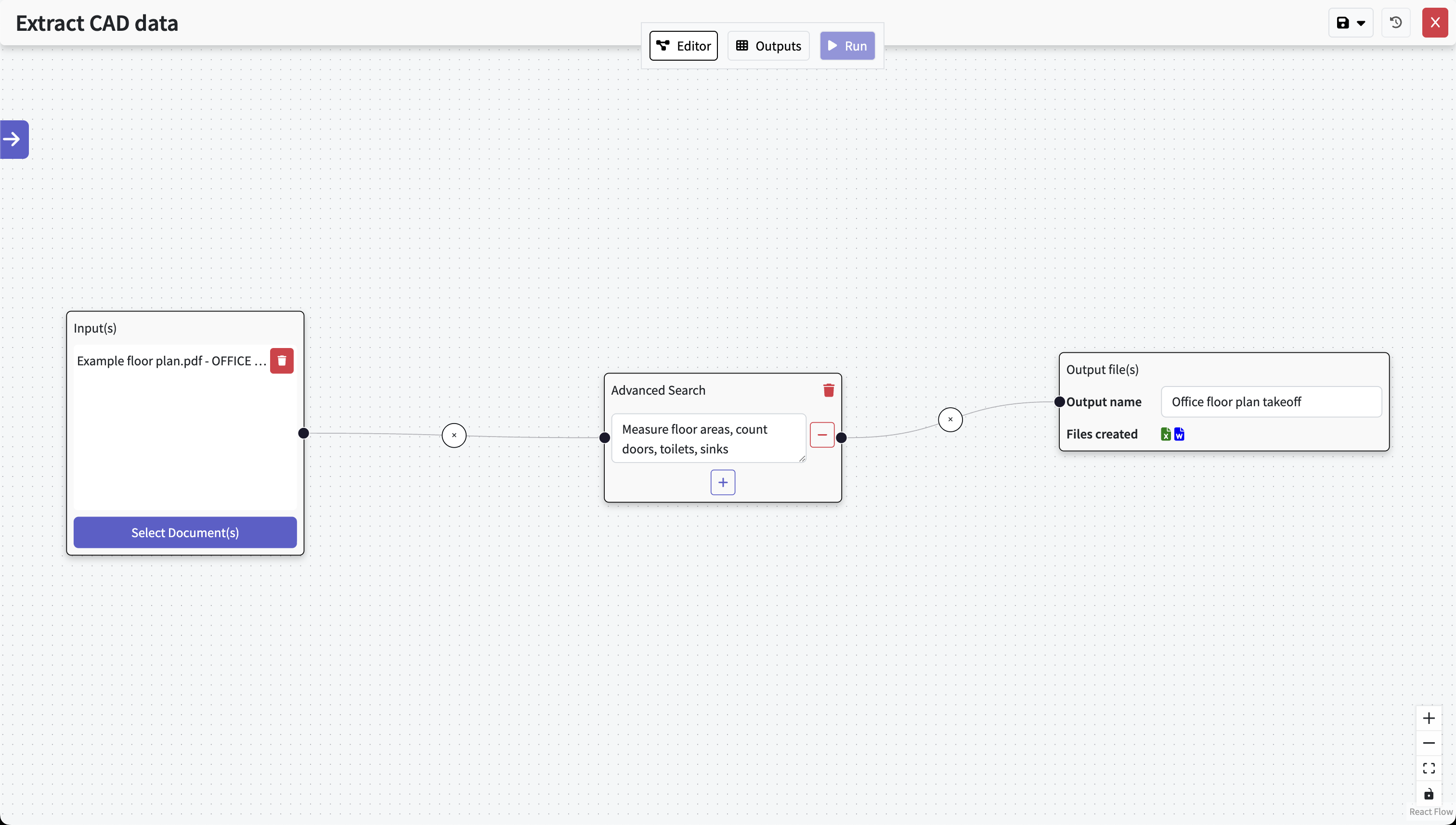

How It Works

- Upload your PDFs — Add plan drawings, schematics, and chilled water schedules you want considered.

- Write your prompt — Tell Civils.ai what you need (for example: “Prepare CHWS/CHWR/CHWP pipe runs by diameter; count valves and fittings; group by floor.”).

- Click “Run” — The platform begins preparing a draft takeoff based on your uploaded drawings and schedules.

- QA review & adjust — Your QA team reviews the draft, fixes any issues, and confirms assumptions before release.

- Share with confidence — Release reviewed drawings and quantities to stakeholders with clear references back to the source PDFs.

Upload PDFs

Drag & drop your drawing PDFs and select Extract CAD data. Works with scanned, historic, and multi-sheet drawings.

Type out your prompt

Type what you need in natural language (e.g. “measure CHWS, CHWR, and CHWP pipe lengths by diameter; count valves, tees, elbows; include insulation class where noted”). Hit Run and the AI performs the takeoff and our QA team reviews the results.

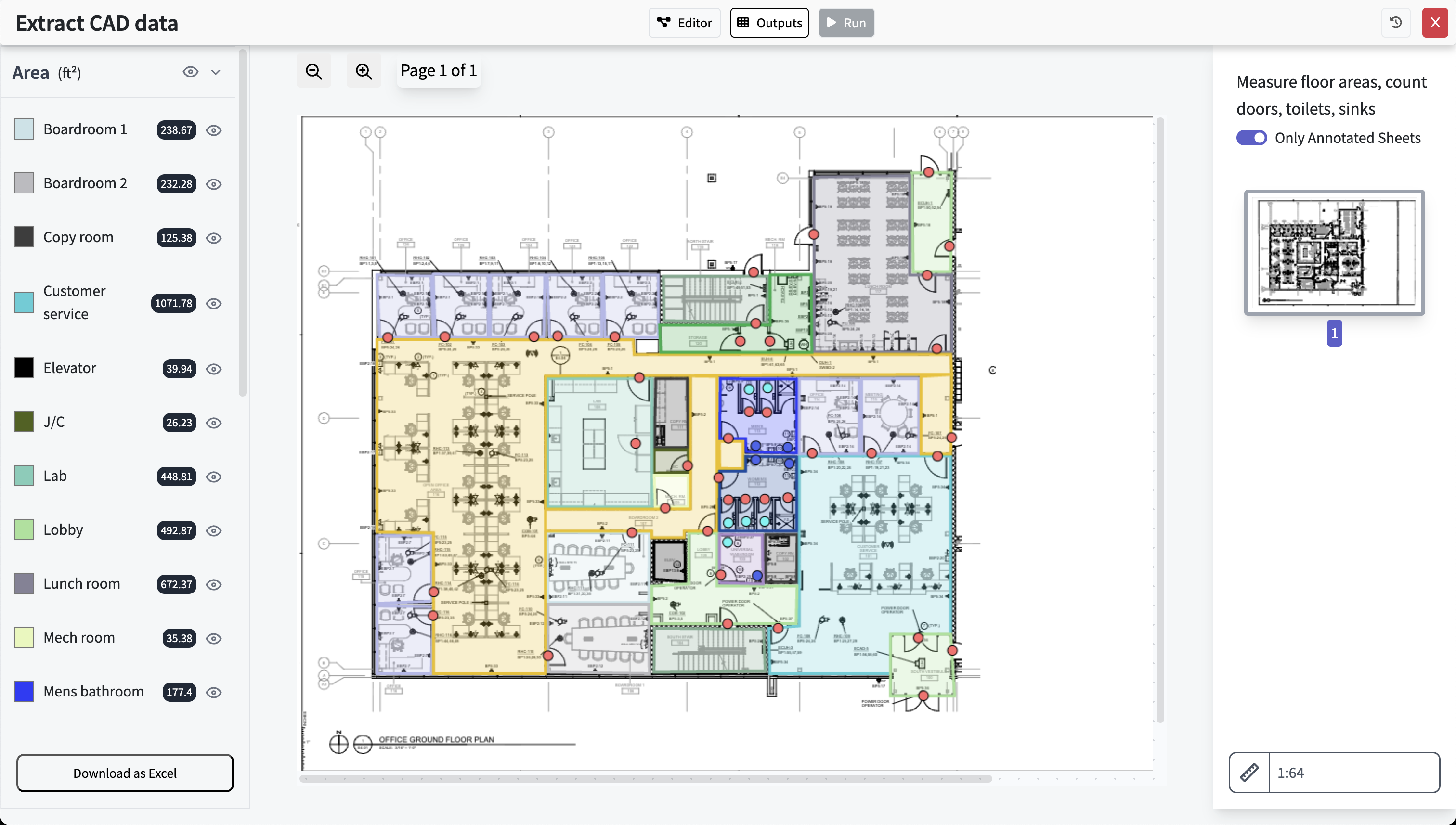

Get results, review & export

What the Draft Takeoff Can Cover

The goal is a clean starting point for pricing—prepared from your drawings and schedules—so your team spends more time refining and less time starting from scratch.

Typical items

- Pipe lengths by service (CHWS, CHWR, CHWP) and diameter

- Counts for valves, tees, elbows, reducers (when shown)

- Breakdown by level/zone and sheet references

- Notes on insulation class or specification if indicated

Clarity about sizes/specs

Pipe sizes, materials, and insulation classes are taken from the plan drawings and specifications you provide. The system does not infer values beyond what is shown in your documents.

What to Expect (and What Not To)

Overview

What you can expect

- A prepared draft takeoff to help your bid

- Clear references back to the drawings and schedules

- Faster internal reviews and fewer back-and-forths

Limitations to note

- Not a 100% automated takeoff—human review is essential

- No inference of pipe sizes/specs beyond what’s shown

- Complex 3D routing/modeling is not supported

- Pipework

- Ductwork

- Cable tray

- CHWS

- CHWR

- CHWP

FAQ

Is this suitable for busy bid periods?

Yes. It prepares a draft quickly so your team can review, adjust, and price with confidence instead of starting from a blank page.

Can we trust the numbers?

Use the draft as a starting point. Your QA team checks and fixes anything that needs attention before releasing numbers to stakeholders.

Where do the quantities come from?

From the PDFs you upload—plan drawings, schematics, and schedules. Everything stays traceable to the source pages for easy review.

What about complex systems?

We don’t infer design intent beyond what’s shown. For standard linear takeoffs and component counts indicated in the documents, the tool prepares a draft your team can finalize.

Prepare Stronger Chilled Water Bids with Civils.ai

Upload your drawings and schedules, write a quick prompt, click run—then let your QA team review and release a clear, traceable CHWS/CHWR/CHWP takeoff.

Civils.ai is an assistive tool for bid preparation. Final quantities and assumptions should be reviewed and approved by qualified professionals.