Materials Lesson on Concrete Creep and Shrinkage

Concrete is one of the main materials utilized in civil engineering construction in the modern age with an annual production of roughly 20 billion tons. A common issue in concrete construction that will always need our attention is creep and shrinkage.

By definition —

Creep: time-dependent deformation due to sustained load

Shrinkage: decrease in either length or volume of a material resulting from changes in moisture content or chemical changes

Concrete is designed to anticipate losses

Shrinkage and creep are two main forms of loss that concrete experiences in its life cycle. Typically, shrinkage and creep are paired together but this article will focus on them separately. Creep is a long-term loss while shrinkage is a shorter-term loss that we will break down a bit later.

Creep

In more practical terms, creep is the increased strain or deformation of a structural element under a constant load. Depending on the construction material, structural design, and service conditions, creep can result in significant displacements in a structure. Severe creep strains can result in serviceability problems, stress redistribution, prestress loss, and even failure of structural elements. Creep can be prevented with the use of higher metals or the use of materials with greater grain sizes. The quantity and quality of paste material is the single most important parameter affecting creep.

Cheat sheet for concrete creep:

-

Long-term pressure or stress on concrete can change the shape of the structure

-

This deformation usually occurs in the direction in the force is being applied

-

Creep does not necessarily cause concrete to fail or break apart

-

When a load is applied to concrete, it experiences an instantaneous elastic strain which develops into creep strain if the load is sustained

-

Creep is a factor for which concrete structures are designed

-

In a creep failure, the material fails at stress less than the maximum stress

-

Creep is a permanent deformation

-

Creep mainly depends upon the temperature to which material is subjected and the time up to which it is stressed

Shrinkage

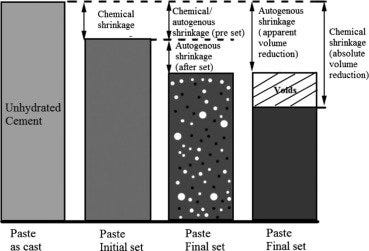

Shrinkage is a loss that causes the volume of a concrete structure to decrease due to the evaporation of water and can cause cracking. It is a time-dependent deformation that requires no external forces to reduce the size of the concrete. In addition to the two main types of shrinkage plastic and drying, there is also thermal contraction, autogenous, and carbonation shrinkage.

In practice, the temperature of fresh concrete a few hours after batching is higher than the temperature of the surrounding environment. The rise in temperature over time is due to the type and amount of concrete used, the pozzolans or slag cement, the size of the member being designed, and the temperatures of the surrounding environment. When the concrete begins to cool, it releases heat, contracts, and decreases in volume. Much like when any material is heated, it typically gets larger with heat and shrinks when it cools. To monitor this type of shrinkage, it is important to be aware of the curing environments changing temperatures.

Pozzolans — Broad class of siliceous and aluminous materials that react chemically with calcium hydroxide to form compounds possessing cementitious properties.

Slag Cements — hydraulic cement formed when granulated blast furnace slag (GGBFS) is ground to suitable fineness and is used to replace a portion of portland cement

Autogenous or chemical shrinkage typically occurs with low water/cement ratio mixes. During cement hydration, the water is rapidly drawn and creates a demand for more water in very fine capillaries which can lead to cracking. This type of shrinkage can easily be avoided by continuously wetting the concrete allowing water to constantly refill the fine capillaries and not dry out. This type of shrinkage is not of much importance and can be ignored. From my research, it is mainly observed for the mass of concrete for the interior of a dam.

Carbonation shrinkage occurs when the calcium hydroxide in the hardened concrete reacts chemically with the carbon dioxide in the air of the surrounding environment. Carbonation shrinkage is typically caused by the dissolution of crystals of calcium hydroxide being replaced by calcium carbonate. As the new product is less in volume than the product replaced, shrinkage takes place. This shrinkage usually occurs in areas with medium humidity and increases strength while decreasing permeability.

The effects of plastic and drying shrinkage are the most important for concrete design. Plastic shrinkage occurs before concrete hardening and drying shrinkage occurs after the hardening. For plastic shrinkage, the cause of quick water evaporation is primarily due to high wind speeds, low humidity, high surrounding temperatures, and high concrete temperatures. Drying shrinkage appears after the concrete is settled and hardened. It typically happens in the first couple of months and decreases over time.

Different types of shrinkage occur over the lifetime of the concrete.

In essence, creep and shrinkage are two major types of concrete losses that are considered in the design. To ensure the construction process runs smoothly, concrete testing is performed and concrete mixtures are developed to withstand as many losses as possible.